Foamie Wooden Boat Evolution:

At Foamie Friends we work hard to try to deliver you the best product possible. We are always looking for ways to better improve our product and to increase durability. While Our first foamies were close in construction methods to what Foamie George designed in the whitewater community in the early 2,000s, we have in time made innovations to the design, making it more durable, and now have a product we can truly call our own. Look below to see how our design has changed over time.

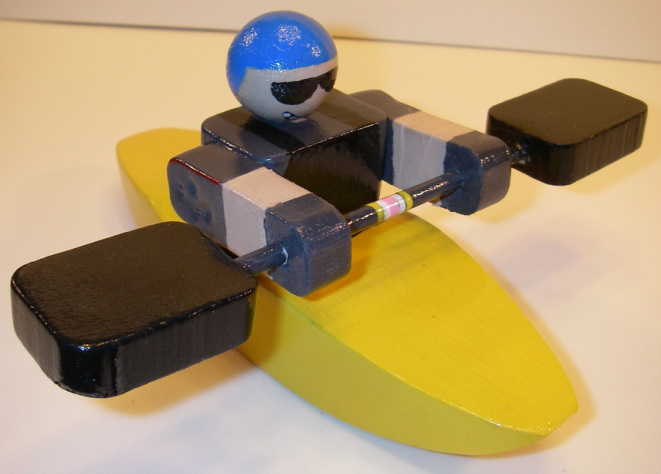

Generation 1:

Only 2 ever got sold, and we tried to refund the buyers of those (they wouldn't take back the money because they were happy). Made completely from 2 pound Minicell. Failed the test of my twin boys in the tub. Foam was just too soft causing premature wear and arms lacked proper support. $530 in foam and water jetting cost in the trash! The cost of research and development.

Only 2 ever got sold, and we tried to refund the buyers of those (they wouldn't take back the money because they were happy). Made completely from 2 pound Minicell. Failed the test of my twin boys in the tub. Foam was just too soft causing premature wear and arms lacked proper support. $530 in foam and water jetting cost in the trash! The cost of research and development.

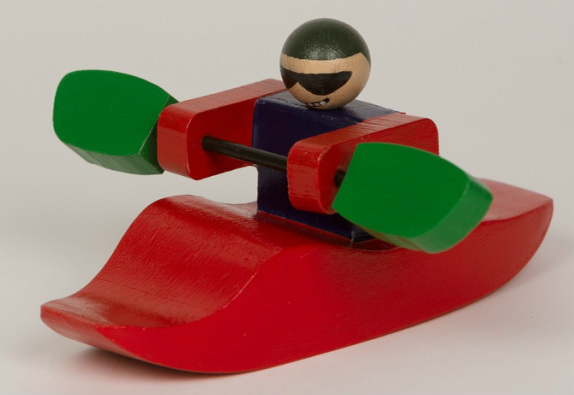

Generation 2:

Replaced the 2 pound Arms and blades, with 6 pound arms and blades. Also new blades were a whitewater shape. New arms were just a bit bigger and worked perfectly. New blade was still a little too big. While 2 pound body never failed, it still would wear prematurely causing me to replace it with 6 pound in future generations.

Replaced the 2 pound Arms and blades, with 6 pound arms and blades. Also new blades were a whitewater shape. New arms were just a bit bigger and worked perfectly. New blade was still a little too big. While 2 pound body never failed, it still would wear prematurely causing me to replace it with 6 pound in future generations.

Generation 3

On the 3rd generation we shortened our longer blades which helped with roll ability, also replaced the 2 pound body with a 3 pound body (waiting for 6 pound bodies to be water jetted). This is also where we had a foamie break through where we no longer had shoulder seams, and 4 shoulder joints extended from one side to the other making the strongest foamie body ever.

On the 3rd generation we shortened our longer blades which helped with roll ability, also replaced the 2 pound body with a 3 pound body (waiting for 6 pound bodies to be water jetted). This is also where we had a foamie break through where we no longer had shoulder seams, and 4 shoulder joints extended from one side to the other making the strongest foamie body ever.

Generation 4

Our 4th generation is where we really started to have everything come together. All foam pieces are 6 pound, and new smaller blade design works awesome. Still was using low VOC assembly methods which I hated to give up.

Our 4th generation is where we really started to have everything come together. All foam pieces are 6 pound, and new smaller blade design works awesome. Still was using low VOC assembly methods which I hated to give up.

Generation 5

With generation 5 we were looking at way to change the building process making it easier to assemble and to make it more durable. We gave up using the low VOC adhesives and replaced it with contact cement (time to bust out the respirator). Many of the kayak hulls were painted with an airbrush. Bodies and boats were assembled after painting eliminating need for extensive taping.

With generation 5 we were looking at way to change the building process making it easier to assemble and to make it more durable. We gave up using the low VOC adhesives and replaced it with contact cement (time to bust out the respirator). Many of the kayak hulls were painted with an airbrush. Bodies and boats were assembled after painting eliminating need for extensive taping.

Generation 6

On generation 6 we gave up on the water based Varnish and replaced it with a high quality Marine Spar Varnish ($160 gallon) which should hold up in water for longer periods and should be much stronger. Heads and blades are now rubberized making them much more durable and are no longer prone to any chipping that happened would happen with wear. The Marine Spar varnish was so much better durability wise when compared to the water based finish.

On generation 6 we gave up on the water based Varnish and replaced it with a high quality Marine Spar Varnish ($160 gallon) which should hold up in water for longer periods and should be much stronger. Heads and blades are now rubberized making them much more durable and are no longer prone to any chipping that happened would happen with wear. The Marine Spar varnish was so much better durability wise when compared to the water based finish.

Generation 7

All foam parts are rubberized for upmost durability. For painting the hulls we are experimenting with Boat paint, and Urethane automotive paint. We will be using clear automotive Urethane Clear Coat on Custom Boats. We also replaced the bamboo chop stick for a solid fiberglass rod since sometimes a paddle shaft could get broken in transport. This new design is durable enough for commercial use. This is the point where I was happy to pursue retailers.

All foam parts are rubberized for upmost durability. For painting the hulls we are experimenting with Boat paint, and Urethane automotive paint. We will be using clear automotive Urethane Clear Coat on Custom Boats. We also replaced the bamboo chop stick for a solid fiberglass rod since sometimes a paddle shaft could get broken in transport. This new design is durable enough for commercial use. This is the point where I was happy to pursue retailers.

Generation 8

The automotive Urethane paint won out for painting the hulls. While it is VERY expensive, it has the upmost durability, UV and chemical resistance, and can withstand constant immersion. We also replaced the spine of the foamie with the fiberglass rod as well. It's just so much tougher and I want to build a product that lasts.

The automotive Urethane paint won out for painting the hulls. While it is VERY expensive, it has the upmost durability, UV and chemical resistance, and can withstand constant immersion. We also replaced the spine of the foamie with the fiberglass rod as well. It's just so much tougher and I want to build a product that lasts.

Generation 9

The only thing that has changed since generation 8 is that all Foamies are water tested and weighted with Tin and Steel for better balance before bodies are glued on.

The only thing that has changed since generation 8 is that all Foamies are water tested and weighted with Tin and Steel for better balance before bodies are glued on.

Generation 10

In Generation 10 we added a final water roll test. We were still having some minor balancing and tracking issues

In Generation 10 we added a final water roll test. We were still having some minor balancing and tracking issues

Generation 11

In Generation 11 we starting marking all boat templates on boat with laser engraver as opposed to tracing on with a pattern from a laser engraver. This led to a more consistent product.

In Generation 11 we starting marking all boat templates on boat with laser engraver as opposed to tracing on with a pattern from a laser engraver. This led to a more consistent product.

Generation 12

In Generation 12 we added center hole to cutting template. We also added the center hole when we water jetted foam bodies to conquer remaining balance issues.

In Generation 12 we added center hole to cutting template. We also added the center hole when we water jetted foam bodies to conquer remaining balance issues.

Generation 13

In Generation 13 we added weights to bottom of boats with any balance or roll issue, and also added a final water test for complete quality control.

In Generation 13 we added weights to bottom of boats with any balance or roll issue, and also added a final water test for complete quality control.

Generation 14

In Generation 14 we tweaked all our boats designs, and stopped producing Double, Touring, and Race boats. For non boaters there were too many choices that often confused people at Farmer's Markets. Double boats just didn't sell. Race boat that was good performer on creek were failures in the tub, and River Runner and Play were merged into new Play Boat design.

In Generation 14 we tweaked all our boats designs, and stopped producing Double, Touring, and Race boats. For non boaters there were too many choices that often confused people at Farmer's Markets. Double boats just didn't sell. Race boat that was good performer on creek were failures in the tub, and River Runner and Play were merged into new Play Boat design.

Generation 15

The only difference in over previous generations is that we tweaked our designs a bit. Also this is when Sunshine Industries took over the majority of production.

The only difference in over previous generations is that we tweaked our designs a bit. Also this is when Sunshine Industries took over the majority of production.

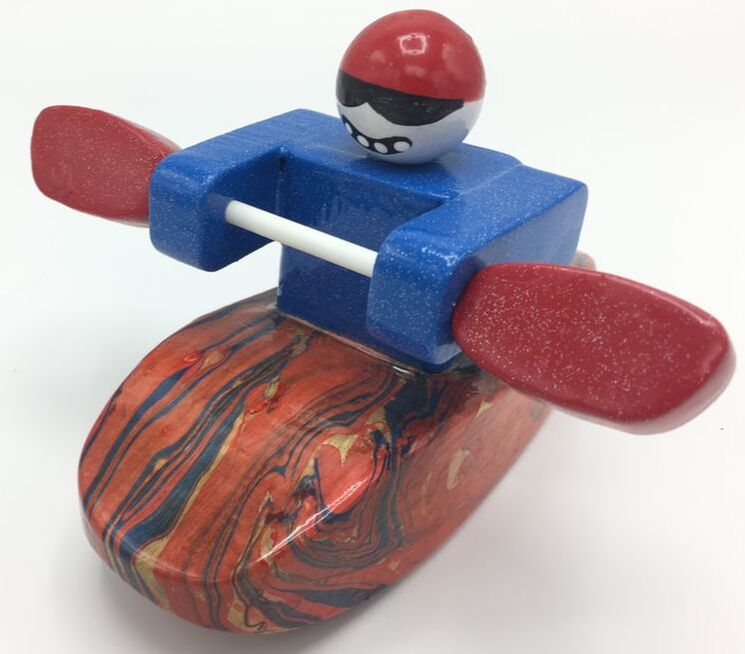

Generation 16

Generation 16 is where Sunshine really started to produce. Lots of Solid colors and natural boats. Also some swirl over natural wood.

Generation 16 is where Sunshine really started to produce. Lots of Solid colors and natural boats. Also some swirl over natural wood.

Generation 17

We tweaked our designs for better performance. We also added an extra water test, and added more weighting. We also changed the way body was rounded.

We tweaked our designs for better performance. We also added an extra water test, and added more weighting. We also changed the way body was rounded.

Generation 18

Continued to modify Creek Boat design. Changed seating position in Spud boat for better performance. The last boats that Sunshine did majority of production.

Continued to modify Creek Boat design. Changed seating position in Spud boat for better performance. The last boats that Sunshine did majority of production.

Generation 19

In generation 19 we were able to get rid of all visible weighting. We also tweaked Creek design again. These were the last of the Solid color boats. Also where Sunshine could no longer produce for me.

In generation 19 we were able to get rid of all visible weighting. We also tweaked Creek design again. These were the last of the Solid color boats. Also where Sunshine could no longer produce for me.

Generation 20

In generation 20 we added white epoxy primer as base and went with only swirl colors. Sunshine continues to sand boats for me, but production is back in house(well in garage). We also added Life Jackets and spray skirts.

In generation 20 we added white epoxy primer as base and went with only swirl colors. Sunshine continues to sand boats for me, but production is back in house(well in garage). We also added Life Jackets and spray skirts.

Generation 21

In generation 21 we changed the arm size to be more realistic, and changed to a smaller diameter paddle shaft.We also added our logo to our life-jacket.

In generation 21 we changed the arm size to be more realistic, and changed to a smaller diameter paddle shaft.We also added our logo to our life-jacket.

Generation 22

In generation 22 we added the Slice Boat to our boat models. I also narrowed the weight range of the wooden boat hulls that I used, eliminating ones that were too heavy or too light. This was done to optimize performance and eliminate any boat that might not perform well.

In generation 22 we added the Slice Boat to our boat models. I also narrowed the weight range of the wooden boat hulls that I used, eliminating ones that were too heavy or too light. This was done to optimize performance and eliminate any boat that might not perform well.